Solutions

to reduce space mission costs

ZARM Technik designs and manufactures AOCS equipment for most large system integrators, space agencies and several universities worldwide as single piece or series for entire constellations. By now more than 150 international missions have been supplied with high performance products, a number of these are in service on orbit for several years.

ABOUT

... Our Philosophy

Beside off-the-shelf products, we offer equipment that is tailored and optimized in a direct dialogue with our customers. Our goal is to determine and implement the best solution for every customer.This point of view is intrinsic to ZARM Technik’s culture and made us a valued partner to satellite primes worldwide.

... Our Quality Policy & Values

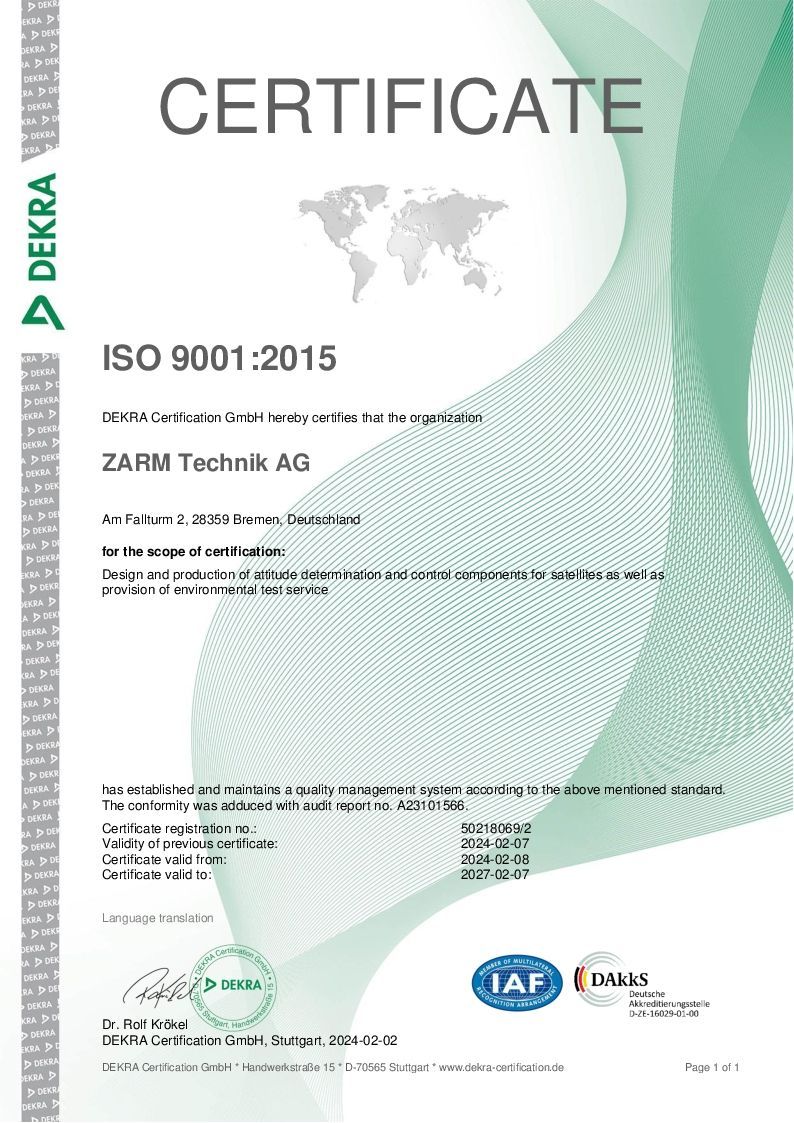

Our space hardware is built to ESA ECSS standards by ESA qualified personnel. To guarantee the quality of our products and services we introduced a quality management system and are ISO9001 certified. We continually strive to improve. We treat our employees in an open, honest and respectful manner. We appreciate the performance of our employees and welcome constructive criticism and suggestions for improvement. Errors are understood as initiation for corrective actions and further improvement. We realize that our thinking and action have a role model function. As an employer, we promote further training, individual initiative and sense of responsibility. We delegate clearly defined tasks, authorities and responsibilities. Together we define and pursue ambitious targets. Management and all employees commit themselves to act according to these guidelines.

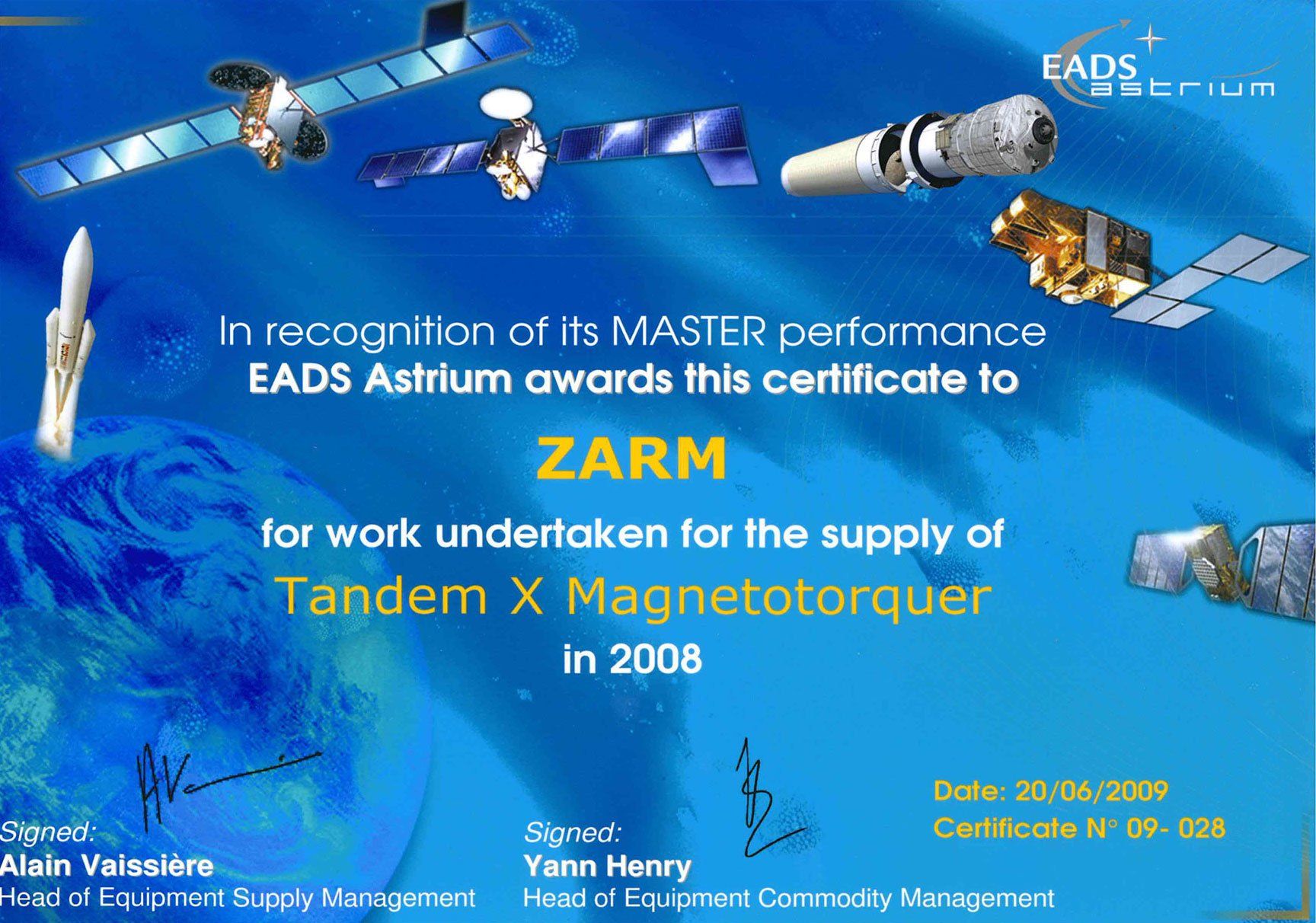

... Our Heritage

ZARM Technik was founded in 1997 as a spin-off from the Center of Applied Space Technology and Microgravity, a University of Bremen institute. We are located in the Technology Park Bremen. The university institute successfully contributed to several German space missions. ZARM Technik's goal was to promote the resulting inventions. Thus, the field of work focused on the development and manufacture of components for attitude control systems of satellites. Since its founding ZARM Technik has become one of the leading manufacturers for Magnetic Torquers and Magnetometers in Europe and worldwide. Benefiting from co-working with leading international research centers, ZARM Technik has become a high-tech enterprise sought-after in the aerospace market.

... Social Responsibility & Engagement

We see our contribution not limited to technological innovation. As a responsible employer, we also take an active role in strengthening the quality of life in the communities where we live and work. Our talented professionals care by supporting educational opportunities. We are proud to be a family friendly employer.

OUR PRODUCTS

Our products combine the highest quality standards and customer services. ZARM Technik ensures cost effective and reliable hardware. With in-total more than 2000 years of flight heritage, none of our products ever failed during test or on-orbit operation.

Magnetic Torquer

Actuators providing a magnetic dipole moment in the range of 0.1Am² to 1000Am². Over 50 designs with flight heritage. Mass and power optimized drive coils.

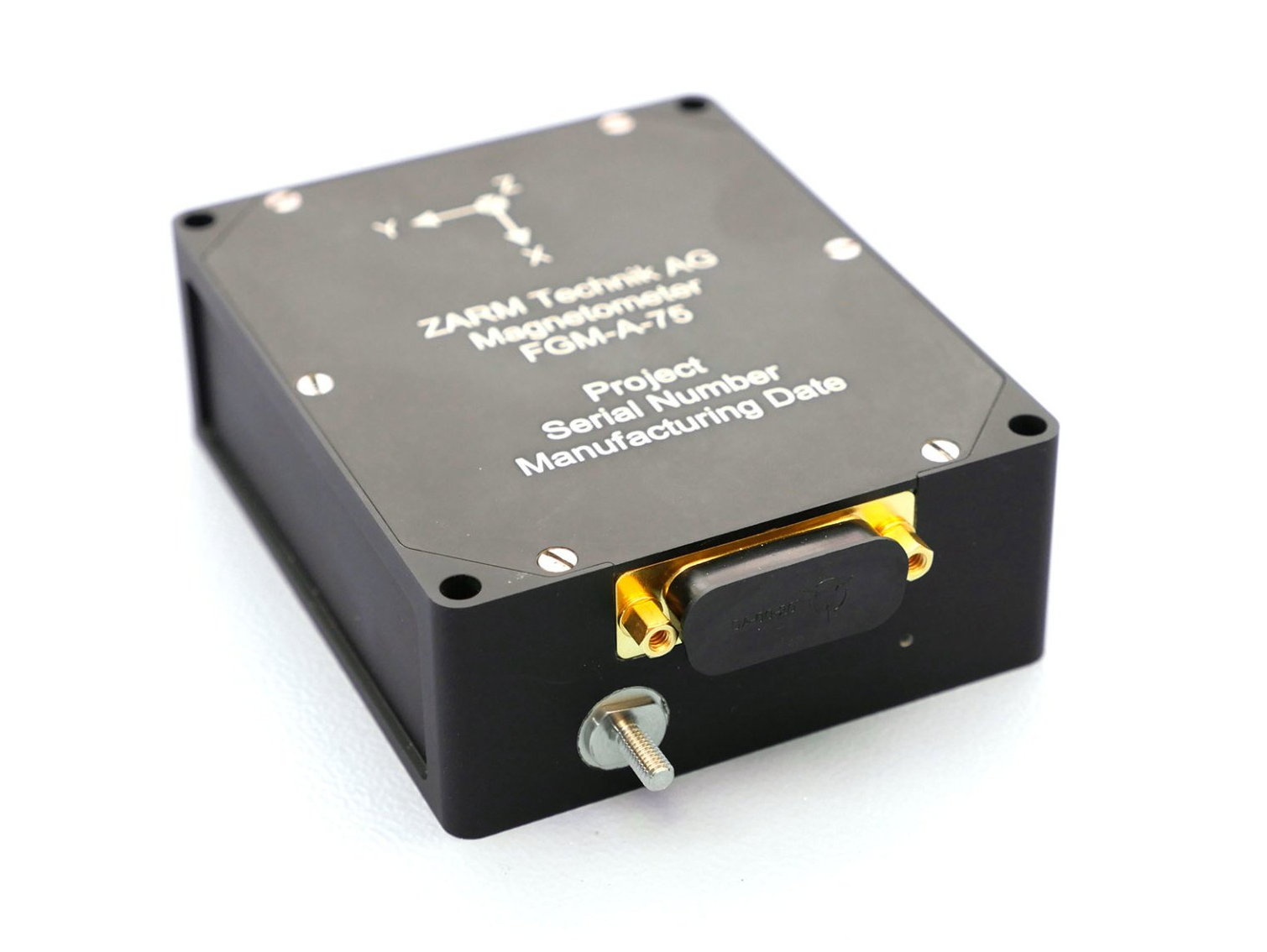

Fluxgate Magnetometer

HiRel analogue sensor for magnetic field measurements. Three axes measurement based on the fluxgate principle. More than 450.000 hours flight heritage.

AMR Magnetometer

Digital sensor for magnetic field measurements. Based on COTS-parts, radiation tolerant up to 20krad TID on part level. TRL9. Cost efficient and shorter lead-times.

Electronic Control Unit for Magnetic Torquers

Digital control and driver unit for three magnetic torquers, designated to generate a specific magnetic torque vector in any desired direction. Based on COTS-parts, radiation tolerant up to 20krad TID on part level. TRL9.

For further information please contact

Martin Kruse, M.Sc.

Project Manager Magnetic Torquer

Martin has a M. sc. in Aerospace Technologies and joined ZARM Technik in 2016 being our Principal Investigator for Advanced Manufacturing ESA activities. Since 2018 he is project manager for our magnetic torquer missions.

Phone: +49 421 218 - 57763

E-Mail: kruse

Dipl.-Ing. Michael Warnke

Project Manager Magnetometer

Michael has a diploma in electrical engineering and joined ZARM Technik in 2009 with focus on magnetometer and electronics.

Since 2013 he is project manager for our magnetometer missions.

Phone: +49 421 218 - 57778

E-Mail: warnke

COMPONENT CUSTOMISING

Customizing to the mission requirements. Our philosophy is to customize and deliver the most efficient magnetic torquer for our clients’ requirements. Drawing from our manifold heritage, we optimize to mass or power, for example. On request, we may also design and build air coils.

Contact us for your customisation

By using our Torquer Request Contact Form

you can send us your mission requirements.

Dipl.-Ing. Peter Offterdinger

Technical Director

Peter has a diploma in electrical engineering and has been at the core of ZARM Technik's development team from the beginning, in 1993. He designed components for more than 110 missions, satellites, the first being BremSat, and Space Shuttle Payloads. His experience spans over 20 years in spaceflight hardware.

Phone: +49 421 218 - 57772

E-Mail: offterdinger

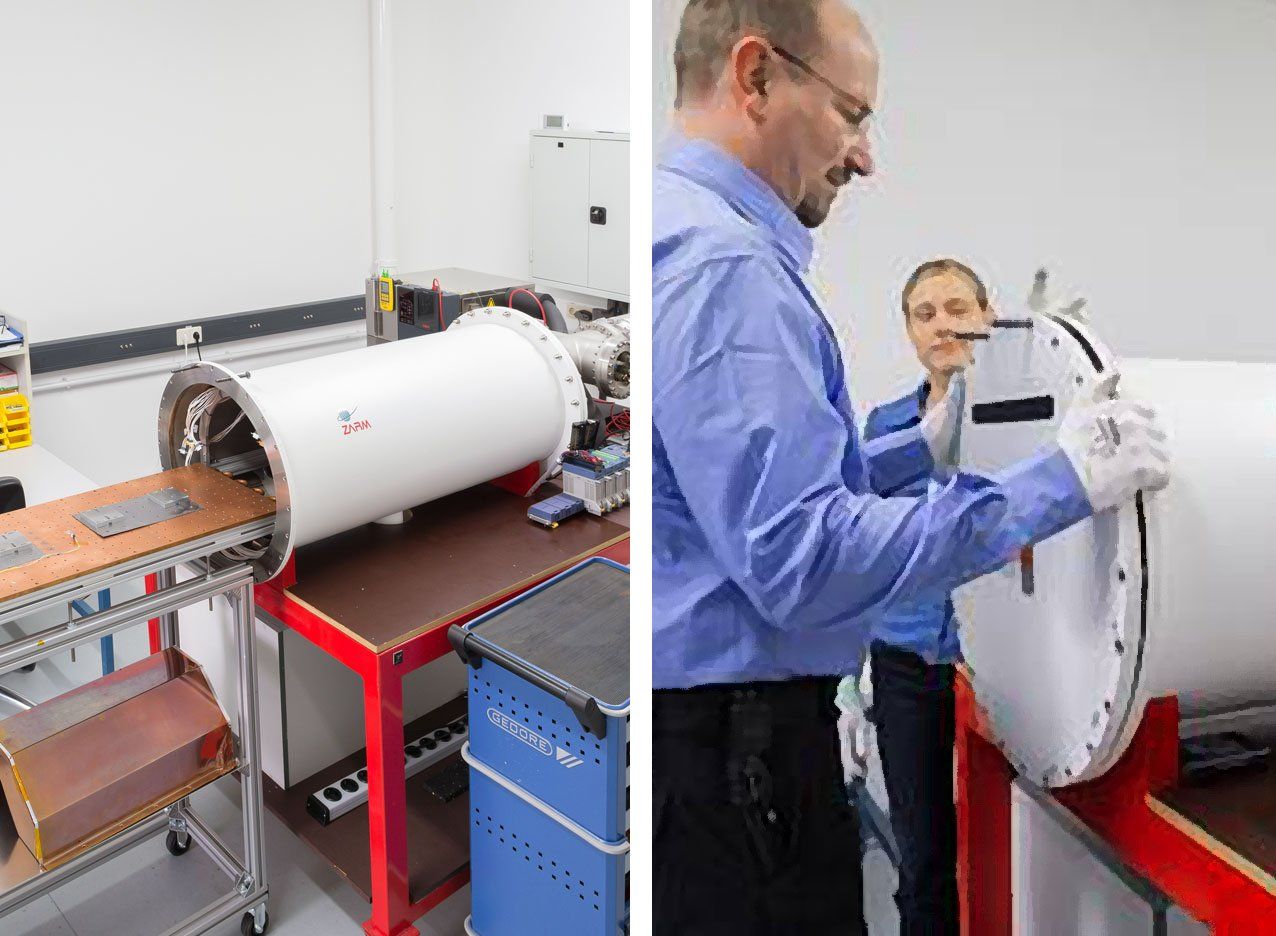

ENVIRONMENTAL TESTING

We. Know. How. - Customer-focussed solutions, Know-how, reliability, and flexibility are our strength in helping you to meet your requirements and expectations. Feel free to contact us and find out if your project can benefit from our services.

Located in the North of Germany, the partnership of ZARM, ZARM Fab, and ZARM Technik conveniently combines a variety of test labs for small and large scale aerospace components. With us you can test your products in vacuum, in extreme and variable thermal environments, under vibration, as well as in hyper- and microgravity.

You will be attended by our qualified ZARM experts with many years of experience in engineering and the performance of aerospace projects. With our broad range of test environments we are able to offer highly individual test designs and always strive for a maximum of flexibility in order to meet your milestones.

You will be attended by our qualified ZARM experts with many years of experience in engineering and the performance of aerospace projects. With our broad range of test environments we are able to offer highly individual test designs and always strive for a maximum of flexibility in order to meet your milestones.

Testing Services

Broad range of aerospace qualification and test services under one roof

- mechanical stress tests (vibration / shaker and fatigue tests)

- environmental tests (thermal vacuum tests)

- static load and acceleration tests (centrifuge / hyper-gravity tests)

- individual combination of qualification and test procedures

Comprehensive one stop shop for technical consulting and engineering support

- competent point of contact and individual assistance by highly skilled and experienced professionals

- development and realization of custom-tailored test regimes

- development and realization of new test concepts and specifications

- flexible scheduling of test series

- design (CAD) and construction of test adapters and components

Convenient infrastructure on site

- mechanical and electrical workshop

- standard clean and air-conditioned laboratories

- provision of standard and special equipment

- meeting rooms, internet access, accommodation

Thermal

Vacuum Chambers

In space, satellite components and materials are exposed to extreme conditions. Extensive tests are required to verify their functional capability and suitability in terms of temperature and atmospheric pressure. A thermal vacuum chamber allows the qualification and acceptance testing of space, and aircraft, products under high vacuum and well-defined temperature scenarios. Such thermal vacuum tests can be fully automated.

Large Thermal Vacuum Chamber

Technical Description:

- thermal range : -60°C to +150°C

- vacuum quality: < 10-5 mbar

- pump down time: 2 h to 10-4 mbar

- thermal cycling gradient: max. 1K/min

- volume: D1450 x W800 x H800 mm

- electrical feed-trough: AWG24 (6 x 50 pins), AWG16 (2 x 8 pins)

- data acquisition unit with up to 90 channels

- stabilized power source and a broad range of measuring equipment

- individual feed through configurations

- ESD protected area

- cleanroom class (ISO 14644-1): ISO 8

Medium Thermal Vacuum Chamber

Technical Description:

- thermal range : -75°C to +150°C

- vacuum quality: < 10-5 mbar

- pump down time: 4 h to 10-4 mbar

- thermal cycling gradient: max. 4K/min

- volume: D1000 x W310 x H205 mm

- electrical feed-trough: AWG24 (3 x 50 and 4 x 19 pins)

- data acquisition unit with up to 90 channels

- stabilized power source and a broad range of measuring equipment

- individual feed through configurations

- ESD protected area

- cleanroom class (ISO 14644-1): ISO 8

Thermal Shock Chamber

Technical Description:

This test chamber has two separately tempered sections and transfers the probes on a lift between hot and cold temperature. This allows steeper temperature profiles and thermal cycling with a high number of repetitions in shorter time.

- thermal range hot chamber: +50°C/+220°C

- Thermal range cold chamber: -80°C/+100°C

- transfer time between chambers: <10s

- volume: W480 x H410 X D660 mm

- data acquisition unit with up to 90 channels

- stabilized power source and a broad range of measuring equipment

- individual feed through configurations

- ESD protected area

- cleanroom class (ISO 14644-1): ISO 8

For further information please contact

Bernd-Carsten Sander

Testing

Bernd-Carsten joined ZARM Technik in 2003. With his experience in electronics and measurement technology he has accompanied the environmental testing of all magnetometer and magnetic torquer projects as well as external testing projects since then.

E-Mail: sander

Services & Facility

Cooperations

ZARM institute, ZARM FAB and spin-off ZARM Technik have a close co-operation and partnership in supporting scientific and industry customers in their testing campaigns with more than two decades of expertise in electrical, mechanical and thermofluid engineering.

Partnership Test Center ZARM

Vibration Test Lab

Hyper-g-Centrifuge